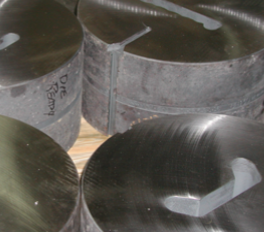

DIE SHOP

The heart of the Rome facility is in the die shop. Our highly skilled technicians are responsible for ensuring that the dies produce high quality extrusions that meet the customers specifications.

6000 SERIES

Profile specializes in 6000 series alloys which are heat treatable and known for strength, machinability, and finish quality.

THE PROCESS

The extrusion process involves heating the aluminum and using pressure to push the metal through a die to create very specific profiles.

EXTRUSION

For over 55 years, quality aluminum extrusions have been produced in the Rome, GA facility. After several expansions and ownership changes, quality and service still remain the number one priority.

The 2700 ton 8″ press and the 2000 ton 7″ press are two of the most technologically advanced presses available for aluminum extrusions.

A state-of-the-art quenching system enables us to cool the aluminum quickly, ensuring we get the aluminum properties our customers need.

OUR STATS

- 40,000,000 lbs/year capacity

- 6063, 6005, 6061 alloys

- 2000 ton 7″ press

- 2200 ton 7″ press

- 2700 ton 8″ press