“Once the desired shape for the finished profile has been developed and the appropriate aluminum alloy selected, an extrusion die, and associated tooling, is produced. In the actual extrusion process, the aluminum billet (a cast “log” of extrusion feedstock) and extrusion tools are preheated. During extrusion, the billet is still solid, but has been softened in a furnace. Note: The melting point of aluminum is approximately 1,220° Fahrenheit (660° Centigrade). Extrusion operations typically take place with billet heated to temperatures in excess of 700°F (375°C), and — depending upon the alloy being extruded — as high as 930°F (500°C).

The actual extrusion process begins when the press ram starts applying pressure to the billet within a container. Hydraulic presses can exert from 100 tons to 15,000 tons of pressure; the pressure capacity of a specific press determines how large an extrusion it can produce.

As pressure is applied, the billet is first crushed against the die, becoming shorter and wider until its expansion is restricted by the container walls. Then, as the pressure increases, the soft (but still solid) aluminum has no place else to go and begins to squeeze out through the shaped die to emerge on the other side as a fully formed profile.

The formed profile is cut off at the die and the remainder of the metal is removed to be recycled. After it leaves the die, the still-hot extrusion may be quenched, mechanically treated, and aged to impart desired metallurgical properties and physical performance.

After sufficient aging, whether in an aging oven or at room temperature, the profiles are moved to other areas of the plant and may be finished (painted or anodized), fabricated (cut, machined, bent, welded, assembled), or packed for shipment.”

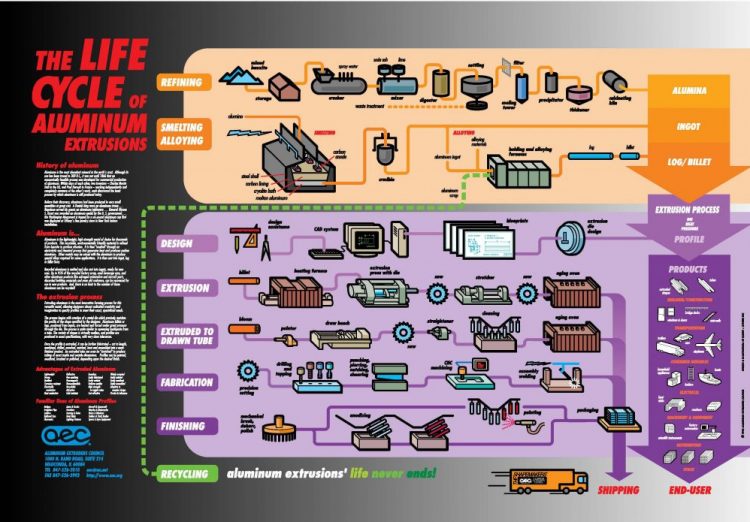

courtesy of aec.org

THE EXTRUSION PROCESS

Profile Custom Extrusions is proud to be a member of the Aluminum Extruders Council